Best Grinding Wheel For Cast Iron . silicon carbide grinding wheel: The more friable types of. “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. This type of grinding wheel works best with steel or cast iron applications. Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. Type 1 (flat wheel), and type 27 (depressed center wheel). how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels).

from www.walmart.com

strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. The more friable types of. This type of grinding wheel works best with steel or cast iron applications. Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels). silicon carbide grinding wheel: how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. Type 1 (flat wheel), and type 27 (depressed center wheel).

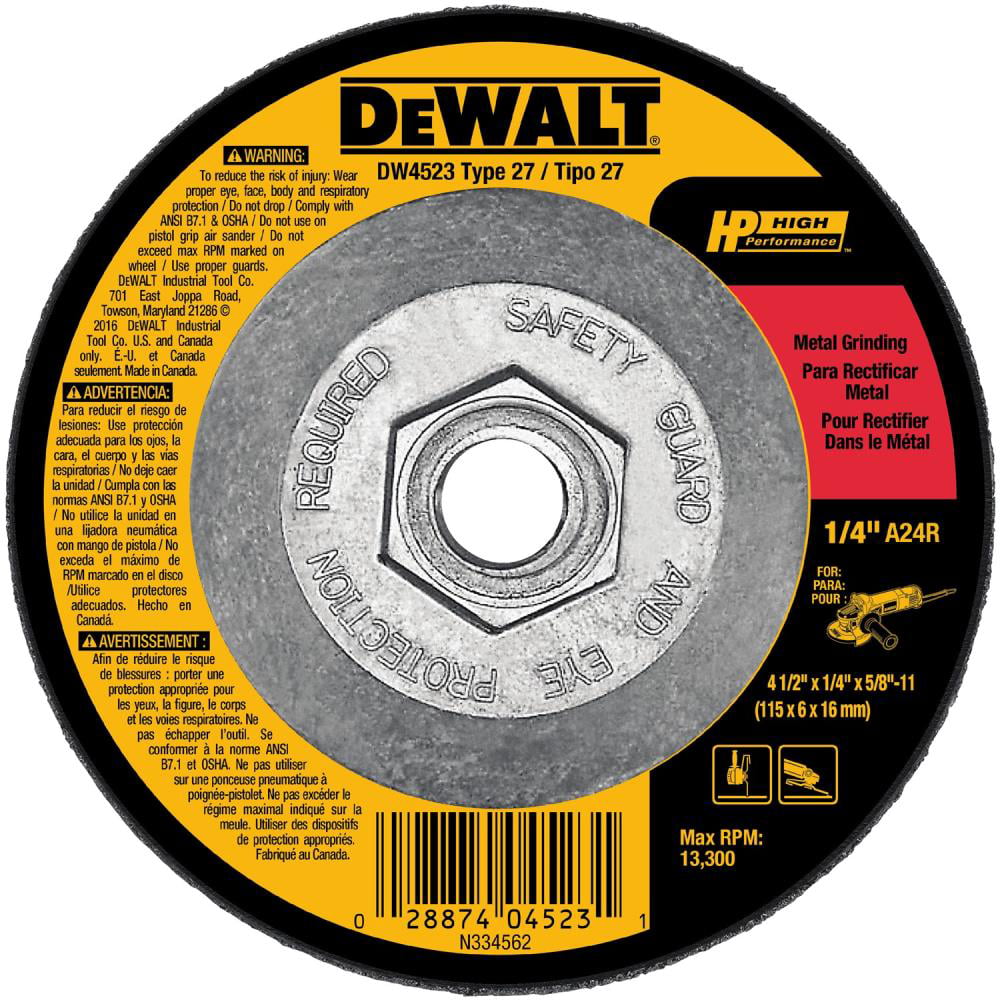

DewaltDW4523 High Performance Metal Grinding Wheel 41/2in x 1/4in

Best Grinding Wheel For Cast Iron Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels). how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. This type of grinding wheel works best with steel or cast iron applications. silicon carbide grinding wheel: The more friable types of. Type 1 (flat wheel), and type 27 (depressed center wheel).

From castgrindsolutions.com

Brazed Diamond Grinding Wheel for Cast Iron Cast Grind Solutions Best Grinding Wheel For Cast Iron The more friable types of. Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. This type of grinding wheel works best with steel or cast iron applications. Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels). how to. Best Grinding Wheel For Cast Iron.

From grindingwheelschina.en.made-in-china.com

500X150X305mm Abrasive Ceramic Bonded Centerless Grinding Wheel for Best Grinding Wheel For Cast Iron Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels). alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. This type of grinding wheel works best with steel or cast iron applications. Silicon carbide grinding wheels are harder but more. Best Grinding Wheel For Cast Iron.

From www.indiamart.com

Cast Iron Grinding Wheel, Heavy Duty Work And Precision Application at Best Grinding Wheel For Cast Iron Type 1 (flat wheel), and type 27 (depressed center wheel). strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. The more friable types of. how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? Silicon carbide grinding wheels are harder but. Best Grinding Wheel For Cast Iron.

From castgrindsolutions.com

Brazed Diamond Grinding Wheel for Cast Iron Cast Grind Solutions Best Grinding Wheel For Cast Iron This type of grinding wheel works best with steel or cast iron applications. how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. alumina type abrasives are the most suitable for. Best Grinding Wheel For Cast Iron.

From www.easygetproduct.com

Top 10 Best Grinding Wheels in 2021 Cut Off Wheel Best Grinding Wheel For Cast Iron silicon carbide grinding wheel: Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels). “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. The more friable types of. alumina type abrasives are the most suitable for grinding high tensile materials such as. Best Grinding Wheel For Cast Iron.

From www.tradekorea.com

vacuum brazed diamond grinding wheel for cast iron tradekorea Best Grinding Wheel For Cast Iron alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? This type. Best Grinding Wheel For Cast Iron.

From metalprofy.com

Top 5 Best Grinding Wheels for Tungsten [July 2024 Review] MetalProfy Best Grinding Wheel For Cast Iron The more friable types of. Type 1 (flat wheel), and type 27 (depressed center wheel). This type of grinding wheel works best with steel or cast iron applications. how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? strong bonds, or hard grades, are recommended for soft materials, small or narrow. Best Grinding Wheel For Cast Iron.

From isharp.en.made-in-china.com

T27 Cutting Wheel & Grinding Wheel for Metal, Stainless Steel & Cast Best Grinding Wheel For Cast Iron “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. silicon carbide grinding wheel: Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? . Best Grinding Wheel For Cast Iron.

From castgrindsolutions.com

Grinding Wheels for Casting Archives Cast Grind Solutions Best Grinding Wheel For Cast Iron alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. how to choose. Best Grinding Wheel For Cast Iron.

From www.easygetproduct.com

Top 10 Best Grinding Wheels in 2021 Cut Off Wheel Best Grinding Wheel For Cast Iron how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? Cbn is a highly durable, synthetic abrasive mineral (for more information read our ultimate guide to cbn grinding wheels). alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. “hard, brittle materials. Best Grinding Wheel For Cast Iron.

From castgrindsolutions.com

Brazed Diamond Grinding Wheel for Cast Iron Cast Grind Solutions Best Grinding Wheel For Cast Iron “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. The more friable types of. This type of grinding wheel works best with steel or cast iron applications. alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. Type 1 (flat wheel), and type. Best Grinding Wheel For Cast Iron.

From chinagrindingwheel.en.made-in-china.com

Casting Grinding Wheel Diamond Tool Foundry Grinding Wheel for Cast Best Grinding Wheel For Cast Iron silicon carbide grinding wheel: The more friable types of. Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. Type 1 (flat wheel), and type 27 (depressed center wheel). This type of grinding wheel works best with steel or cast iron applications. strong bonds, or hard grades, are. Best Grinding Wheel For Cast Iron.

From www.winkingde.com

GRINING WHEEL Grinding Wheel For Cast Iron GRINDING WHEELS, PEGATEC Best Grinding Wheel For Cast Iron strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. Type 1 (flat wheel), and type 27 (depressed center wheel). This type of grinding wheel works best with steel or cast iron applications. Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with. Best Grinding Wheel For Cast Iron.

From www.easygetproduct.com

Top 10 Best Grinding Wheels in 2021 Cut Off Wheel Best Grinding Wheel For Cast Iron strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. This type of grinding wheel works best with steel or cast iron applications. Type 1 (flat wheel), and type 27 (depressed center wheel). silicon carbide grinding wheel: Silicon carbide grinding wheels are harder but more brittle than aluminum oxide,. Best Grinding Wheel For Cast Iron.

From www.bestdealradar.com

20 Best Grinding Wheels For Bench Grinders Of 2024(Reviews) BDR Best Grinding Wheel For Cast Iron strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. Type 1 (flat wheel), and type 27 (depressed center wheel). silicon carbide grinding wheel: “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. Cbn is a highly durable, synthetic abrasive mineral (for. Best Grinding Wheel For Cast Iron.

From www.leevalley.com

Norton 3X Grinding Wheels Lee Valley Tools Best Grinding Wheel For Cast Iron strong bonds, or hard grades, are recommended for soft materials, small or narrow areas of contact, or longer wheel. “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. Type 1 (flat wheel), and type 27 (depressed center wheel). silicon carbide grinding wheel: Silicon carbide grinding wheels are harder but more brittle. Best Grinding Wheel For Cast Iron.

From www.diamonds-tool.com

1000mm Diamond CBN Grinding Wheel Chilled Cast Iron With Steel Core Best Grinding Wheel For Cast Iron “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. silicon carbide grinding wheel: how to choose the right cutting wheel based on wheel types, grain quality, grinder, and cutting material? This type of grinding wheel works best with steel or cast iron applications. alumina type abrasives are the most suitable. Best Grinding Wheel For Cast Iron.

From www.gasandsupply.com

Pferd Grinding Wheels For Steel, Cast Iron Performance Line Sg Best Grinding Wheel For Cast Iron Silicon carbide grinding wheels are harder but more brittle than aluminum oxide, offering a sharp cut with a consistent finish. alumina type abrasives are the most suitable for grinding high tensile materials such as steel and ferritic cast irons. “hard, brittle materials generally require a wheel with a fine grit size and a softer grade. The more friable types. Best Grinding Wheel For Cast Iron.